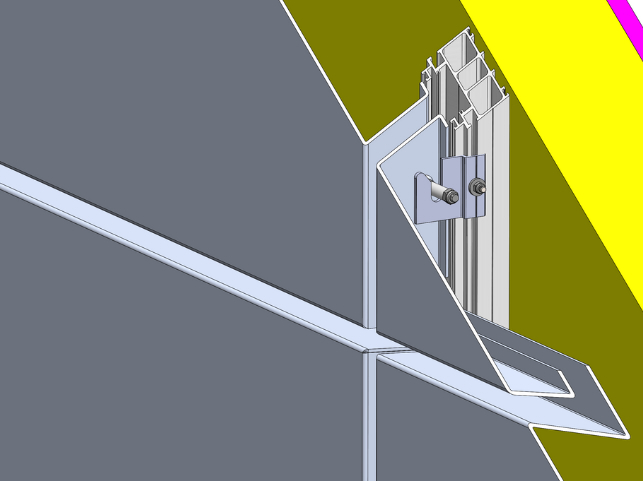

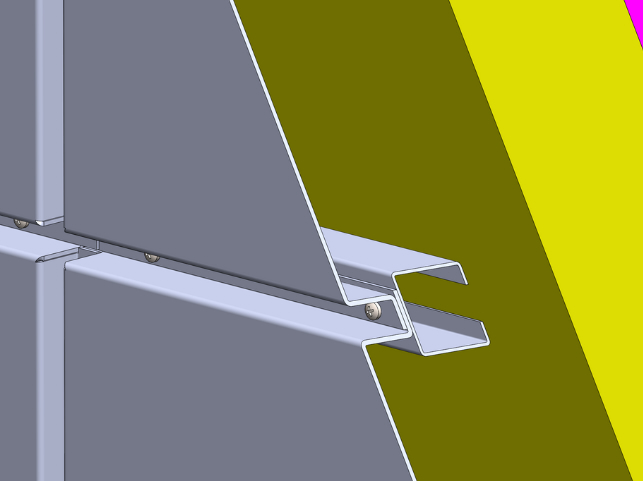

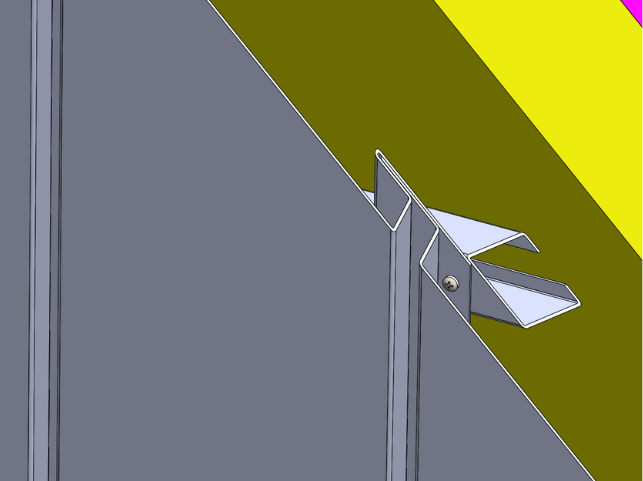

The Gilmours Hook and Pin panel is a single-skin cladding panel, with integrated hanging system.

The panel is formed to be supported from its edges using integral hidden fixings within the 72mm panel depth (as standard).

The hidden fixing method results in assembled horizontal and vertical joints of 20mm (as standard).

The hanging system allows the side-to-side panel installation to be independent whilst allowing for bottom to top installation of an independent stack.

The system incorporates a managed drainage system to maintain the surface finish from weathering.

It is possible for a panel within a stack to be demountable after original installation.

The hidden hook and pin system is engineered to suit the required panel format and can be set on an option of rail types to suit either direct substrate connection or spanning requirements.

This high level of variability allows for the effective & efficient application of landscape or portrait format panels whilst considering the efficient use of materials to obtain a high-performance application.

Rainscreen Cladding Systems

Gilmours rainscreen cladding systems are developed to meet the exacting performance and aesthetic standards of modern façade design.

The different panel system types available offer options as to what can be achieved and are customisable to suit your design intent.

The principles are ideal for:

- Industrial

- Commercial

- Modern architecturally driven developments

They are ideal for modular façade applications whether singular or repeat in nature. The panels can offer clean, contemporary façade solutions with precise panel alignment.

The panels are manufactured using robust, durable raw materials and are finished with expert techniques. The front-end design & engineering through to production of the panels can offer flexibility in format, patterning and finishing whilst achieving fast installation for your site alongside durable and performance driven characteristics.

Our Rainwater Management Systems are designed to work seamlessly with our rainscreen cladding range, ensuring performance, consistency and aesthetic continuity across the full building envelope.

The Gilmours Kassett is a single-skin cladding panel.

The panel is formed to have recessed & overlapping module joints, 40mm deep x 20mm wide (as standard) offering a discrete method of fixing for both landscape and portrait format panels.

This effective and efficient panel allows for quick installation and easy panel replacement.

The side-to-side install direction can be customer driven and is bottom to top install for best weathering overlaps.

The Gilmours Plank is a single-skin cladding panel.

The panel is formed to have interlocking and concealed fixings within the module joints, 35mm deep (as standard).

The concealed fixing location within the assembled joints can offer open or closed modules, normally sized from 2mm to 20mm wide (as standard).

This hidden fixing method allows for a quick directional installation but maintains this as an effective and efficient panel.

The interlock on the longest edge means that the panel can be applied in horizontal or vertical formats with side to side install direction being customer driver or top to bottom installation to allow for the optimum joint weathering detail.

The Gilmours Shingle panel is a single skin interlocking cladding tile.

The panel is formed to have a fully concealed fixing method within its 30mm module interlock (as standard).

The thin material nature of the shingle panel means that the depth is driven by the hemmed interlock zone which contains the clip fixing bracket that is installed onto your substrate material.

The panel is available in different shape formats e.g. rectangular, square, diamond with the interlock directions being driven by the weathering requirements of the joint positions.

The principles of the joint detailing can create a textured, layered, overlapping appearance that evokes traditional craftsmanship with a modern twist.

Rainwater Management Systems

Gilmours gutter and downpipe systems are positioned to meet the necessary performance and longevity to operate in the most stringent of environments.

With supply option types being focussed on the commercial and industrial sectors the Gilmours system offerings are unique and can be adapted to your design intent.

The product manufacture is focused on using the appropriate aluminium alloy which is suited to the supply purposes of high-performance gutters and downpipes.

The primary advantages of aluminium in this context include:

- Fabrication characteristics

- Finishing options

- Weight saving features

- Minimal ongoing maintenance.

Aluminium is ideally suited to the majority of situations as it naturally forms a protective oxide layer, which is self-healing if damaged.

Where requested:

- Design & technical assistance can be provided

- Hydraulic design of the gutters can be verified

- Layout and installation drawings can also be provided to suit the design to manufacture requirements.

All components are inspected before leaving the factory and should be tested in accordance with the relevant local authority by the contracting team.

Gutter outlets and flow zones should be inspected and cleaned periodically by the responsible site team. Inspection would be expected more frequently if in more aggressive environments and near foliage/trees that can add to blockages.

Gilmours expertise in construction metal forming extends beyond guttering to our Rainscreen Cladding systems, delivering coordinated solutions for complete building envelope performance.

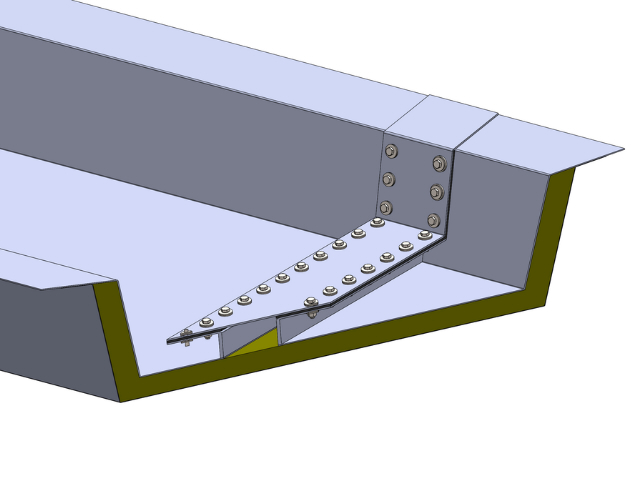

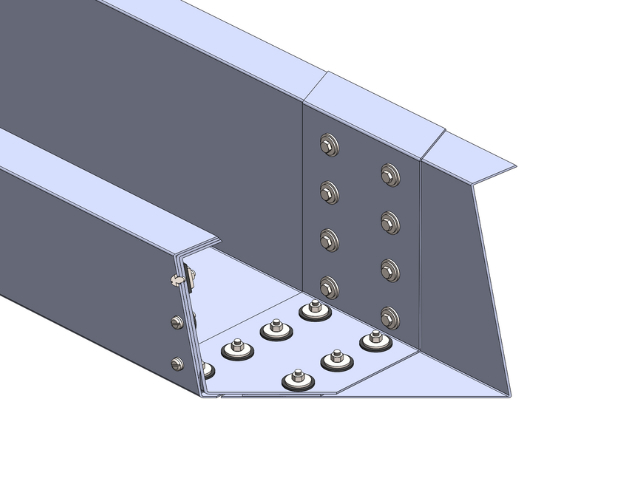

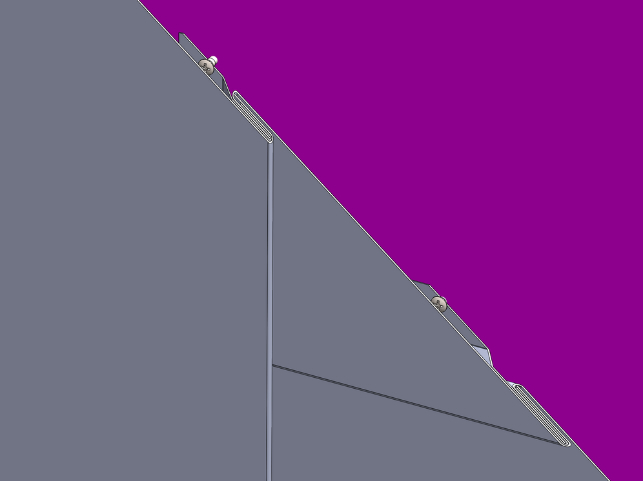

The Gilmours long length gutter system is based on the principles of our weir joint design. This gutter type is primarily focussed on use in parapet and valley roof areas. The detailing method for this system allows extra-long lengths of the single piece gutters to be manufactured. The maximum length of gutter is essentially down to available transportation (in excess of 20m per gutter have been made).

Each length of gutter is of a fully welded construction and the use of our specially designed expansion weir joints eliminates the normal butt joint, and since there is no sole holing, the usual source of leakage is eliminated. The exact section configuration can be supplied suit the requirements of the designer, up to a maximum of 2000mm girth. All stop-ends, outlets, and detailing accessories can be factory welded to increase security.

Being all welded, the gutters can be laid without falls. Depending on site conditions, gutters can be self-supporting (or laid on straps). The thickness of the gutter can be considered to suit the requirements of your available supporting method but are normally manufactured in 2mm thick aluminium but can be supplied in up to 6mm thick if required.

As the long length gutters are modular, lightweight and simple to handle, there is a minimum amount of sitework. When appropriate preparation is carried out the gutters are generally craned into position, laid in place, fixed, sealing strip applied at expansion joints and weir plates installed.

Insulated Long Length Gutter System

Insulated Long Length Gutter System

The Gilmours insulated aluminium gutter system brings together all the benefits of our long length gutter system, and an application of an assured level of insulation which are combined under controlled conditions.

The components of the long length gutter system skin, insulation layer and internal liner are brought together to combine into a transportable assembly. The insulation can be supplied in a type to suit the required roof specification generally to achieve a required “U” value. The liner can be manufactured from a variety of materials, generally to suit the building interior. The assembly can be bonded together or mechanically combined only, driven by the needs of the end user. Lapping details are generated for modular joints layers to ensure continuity of insulation is achieved.

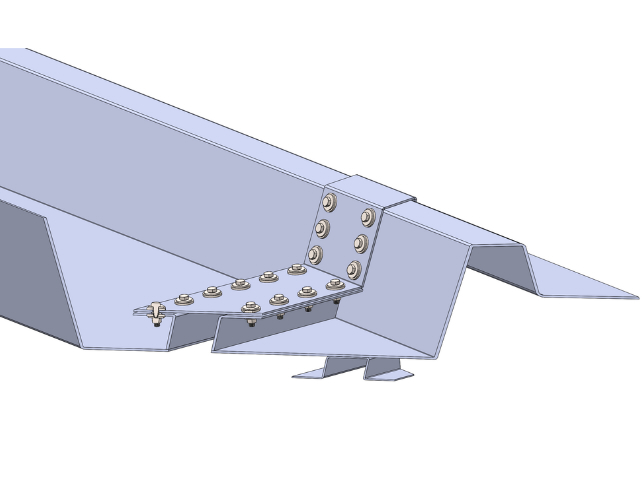

Commercial & Industrial Gutter Systems

Commercial & Industrial Gutter Systems

Gilmours can provide single skin gutters with bolted joint details to suit your sectional design requirements. These gutter details are generally focussed on commercial and industrial use but can also be used in any architectural detailing. The principle of press brake forming to shape enables long lengths of up to 6m to be achieved in single parts. All stop-ends, outlets, and detailing accessories can be factory welded as part of the manufacture process. Each length is pre-holed, prior to powder coating, to suit bolting the joints together on site with the sealed butt-strap arrangement. This detailing principle is ideal for boundary wall details but can also be used in parapet, external eaves & valleys if required.

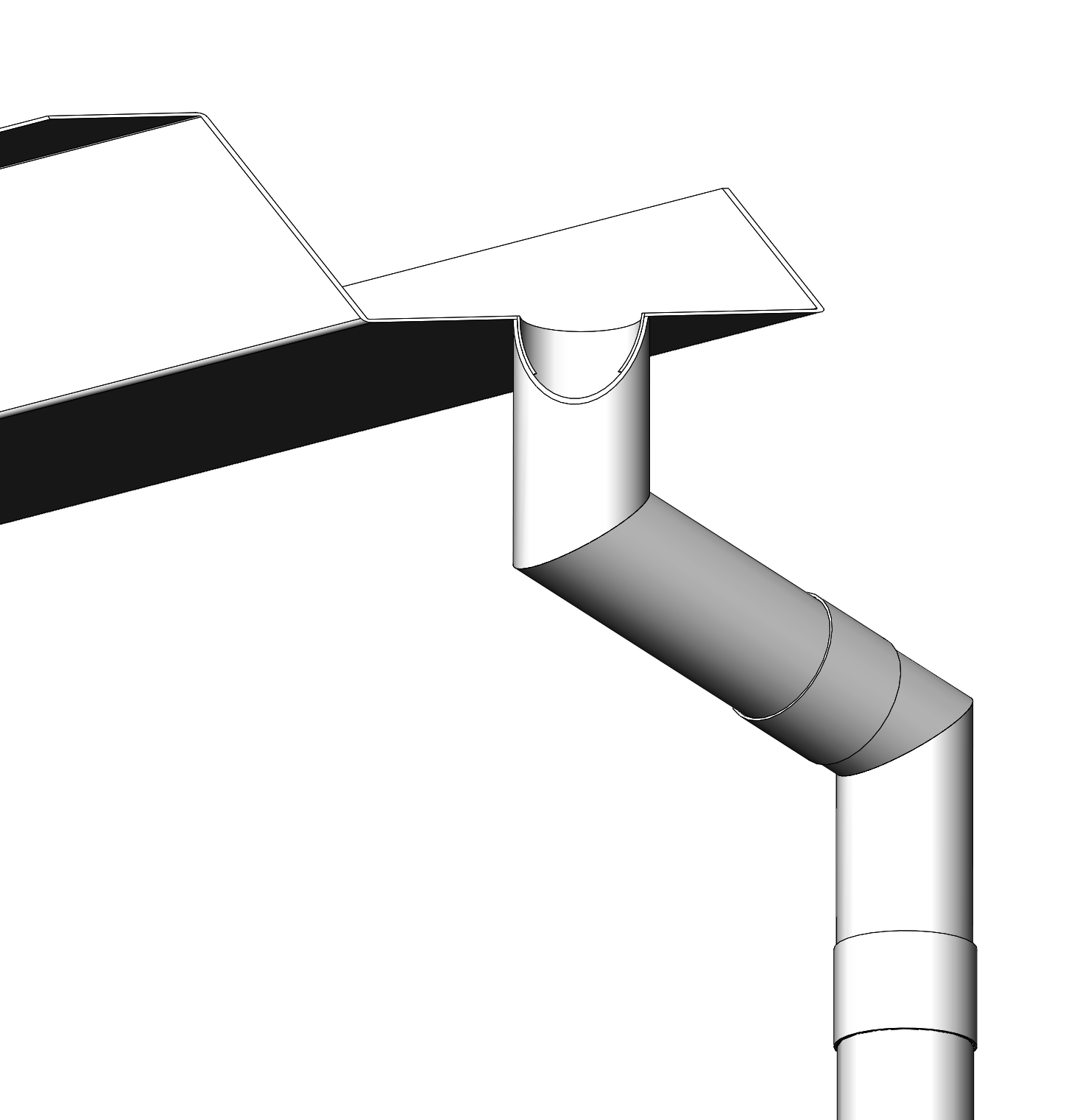

The Gilmours downpipe system can be interlinked with any of the gutter systems offered. The standard available shapes of downpipes are round, square or rectangular. Extruded aluminium sections are used to manufacture the downpipes to the required lengths and detailing prior to powder coating. Where stacks of downpipes are required, these can be provided with external or internal joints dependant on the aesthetic desired. The connectivity of the downpipe to the substrate can vary on availability per type of shape and jointing but are generally; flush direct fix / flush secret fix / flush clamp fix / offset direct fix / offset clamped. Accessories can be provided to suit gutter to downpipe requirements and for inspection and termination requirements. (e.g. shoes, rodding eyes, bends, swannecks, tee junctions, branches, hoppers). Engineered as part of our complete rainwater goods offering, Gilmours downpipe systems reflect our commitment to high quality construction metal forming and architectural detail. Explore more on our Solutions page or contact us to bring your specification to life.

Materials

Finishes

Patterns + Textures

Colours

Get Inspired

View our latest facades, panel systems and architectural metalwork in context. Explore the projects that shape our work.

Hook and Pin System

Hook and Pin System

Kassett Panel System

Kassett Panel System

Plank Panel System

Plank Panel System

Shingle System

Shingle System

Long Length Gutter System

Long Length Gutter System

Downpipe System

Downpipe System